Ritual Part 3 - Lighting Up Ritual: Our First Candle-Making Attempt

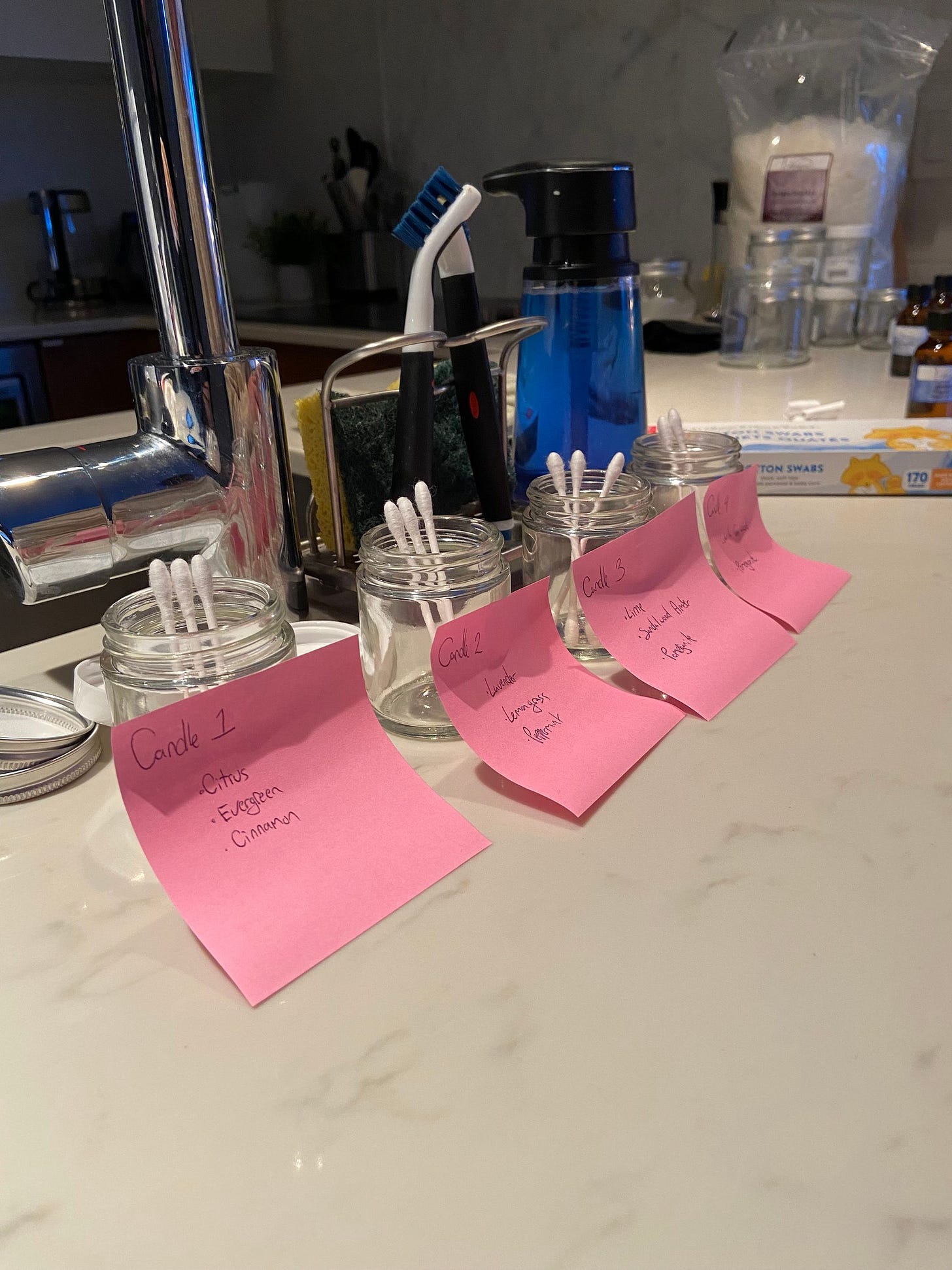

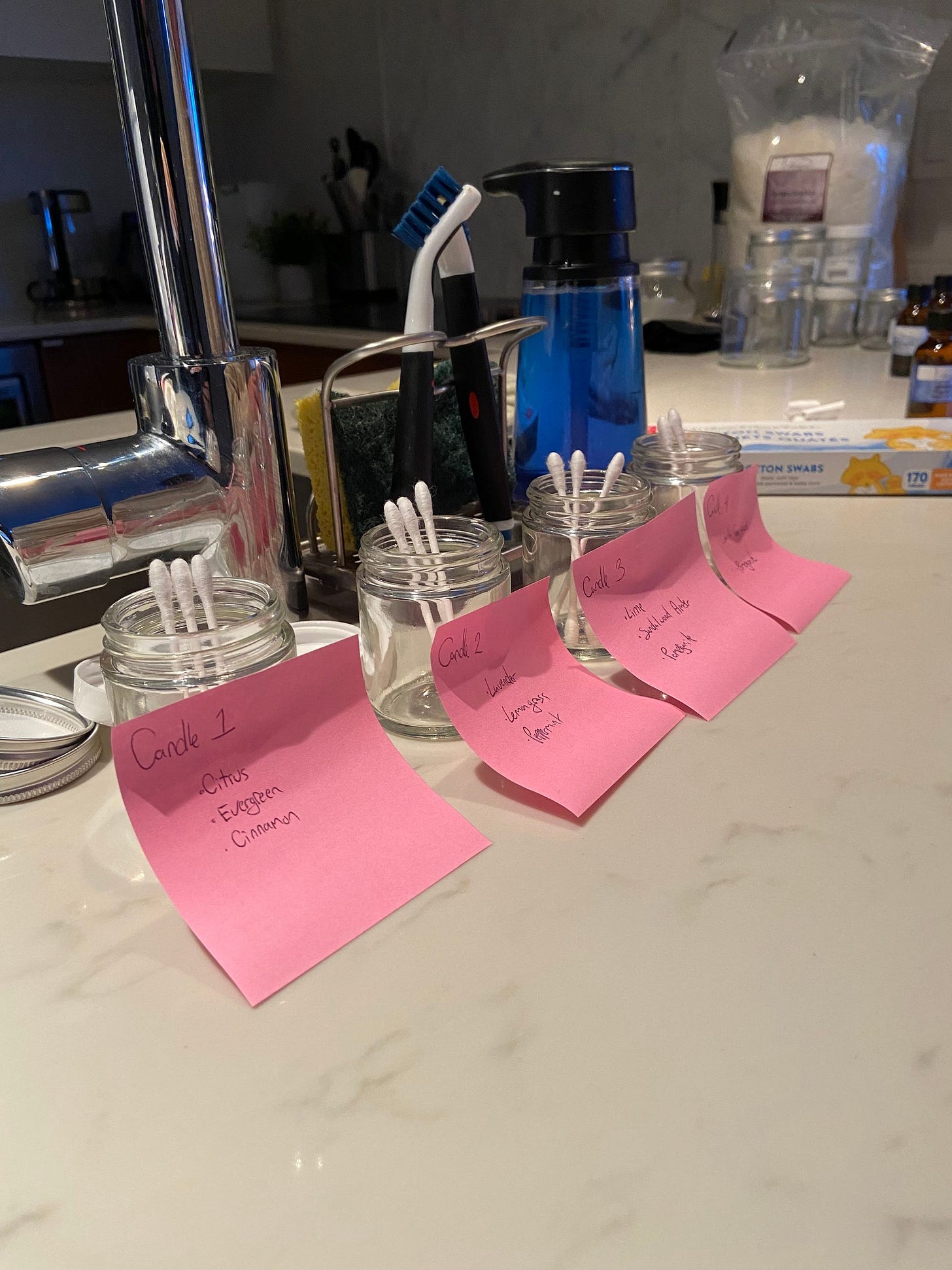

Our first attempts at the candle component.

Hey there, welcome back! On the ongoing journey to bring Ritual into reality, we've already stumbled, triumphed and learned a tonne along the way. After our last chat about creating the Ritual board and cards, this time, we'll take a trip through the process we went through trying to get the candles for Ritual manufactured.

Lessons Learned

Scale is everything and should be considered at every step along the way. Inability to scale simply means an alternative needs to be found.

It’s a good idea to try to do things yourself in the beginning. Understanding the basics is invaluable when it comes to working with others later and being able to communicate exactly what you want from them.

I. The Homegrown Approach

When we kicked off this project, we were dead-set on keeping everything local. It made sense for us – we were going for a high-quality feel, and being able to see and touch every aspect of our process just sounded right. We contacted every candle-maker we could find, only to discover that the cost of a locally made, bespoke candle would simply be commercially unviable. It was disappointing. Still set on staying local though, we saw no other solution than to roll up our sleeves and dive into making the candles ourselves.

Learning from my earlier mistake of designing Ritual’s board without research, I prioritized it this time. I initially spoke with my mum, who had dabbled in candle making as a hobby, and she let me in on a secret - making candles is tougher than it looks. With her advice in mind, I went all out, soaking up knowledge from YouTube, poring over articles, and religiously checking out the r/candlemaking subreddit.

A gem among the resources was candlescience.com – a goldmine of candle-related info that really helped shed some light on the various waxes and wick sizes.

II. The Great Supplier Hunt

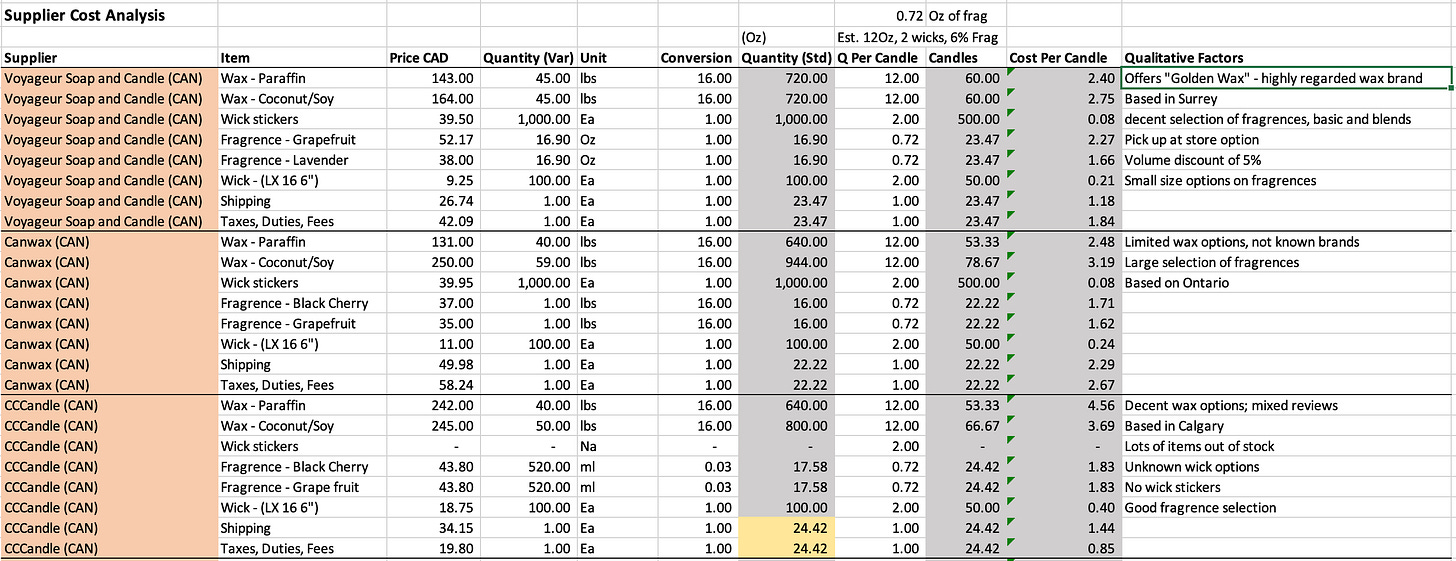

Then came the quest for finding the best supplier. I needed to find a balance between cost-effectiveness and quality. My accounting background coming into play, I performed a quick cost analysis and added in some qualitative notes based on reviews, product offerings, etc. You can see a screenshot of the analysis for one supplier below.

Pretty quickly it became clear that Voyageur Candle & Soap Co. was going to be the best option for us. A combination of great product selection, decent prices, and an easy commute made it the perfect fit. On Saturday, we hit the road and came back loaded with premium candle wax, fragrance oils, and all the tools we needed.

Then back at the apartment we spent several evenings experimenting with different wax formulas, fragrance blends, and temperatures, all while meticulously recording our observations. However, as fascinating as this phase was, we soon realized that this was simply too time-consuming to scale.

III. Looking Beyond

The next step was pretty clear. Local production was too expensive and making the candles ourselves was a massive time-sink. We had to consider outsourcing. As we turned our sights towards Asia, our journey got quite a bit more interesting, even bumpy at times - a story that deserves a post all its own.

Not only that, but we also decided it was time to start thinking about branding. In the next post, I’ll delve into developing Ritual’s brand and after that, we’ll get into the challenges of outsourcing our candles.

Stay tuned! Don't forget to subscribe so you won't miss it, and as always, thanks for reading.